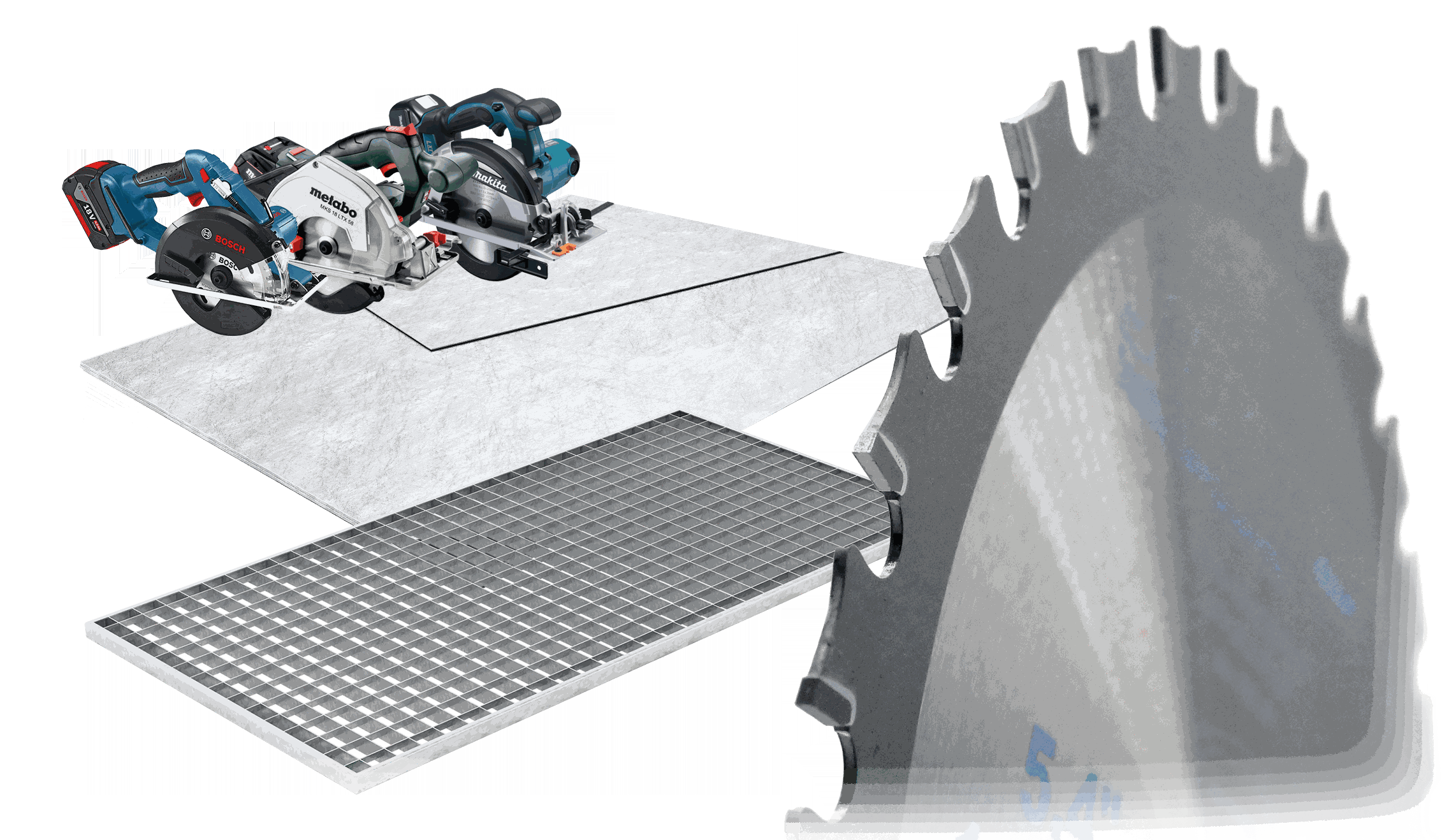

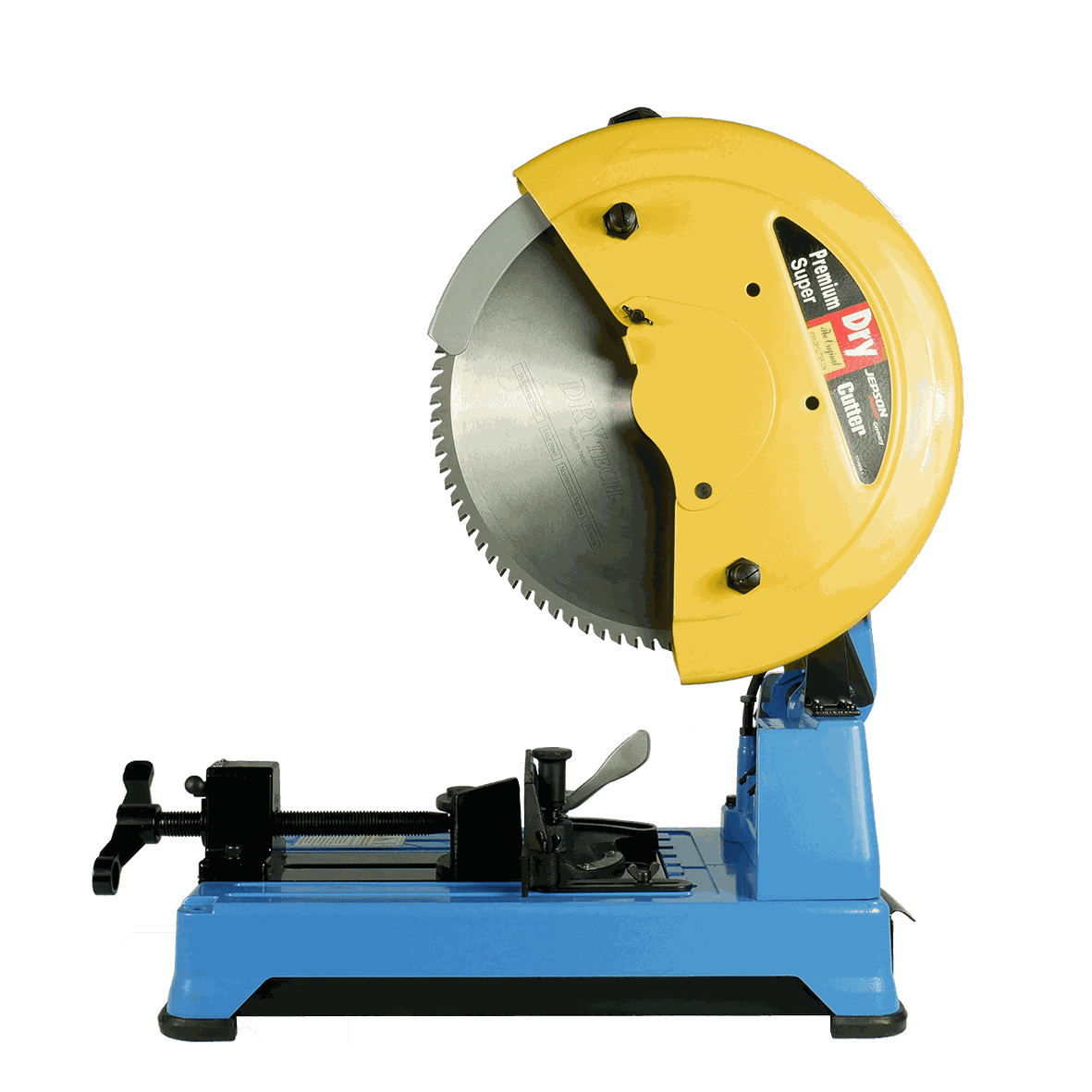

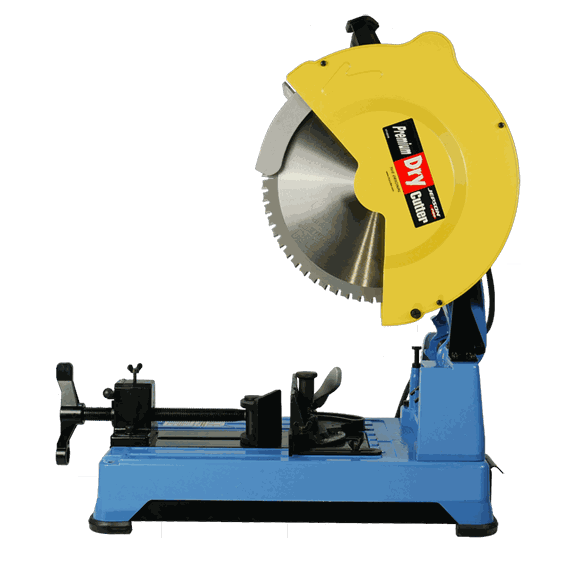

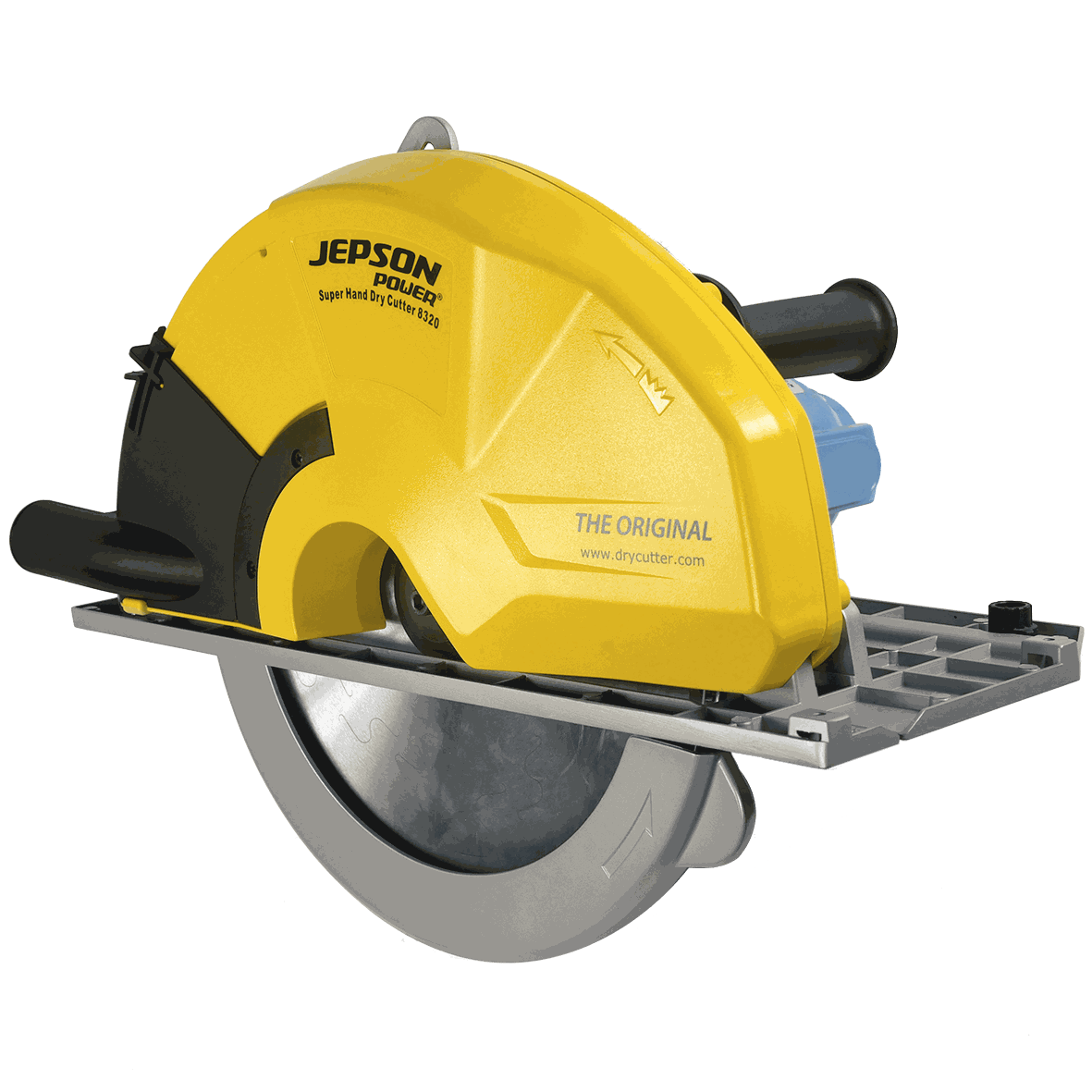

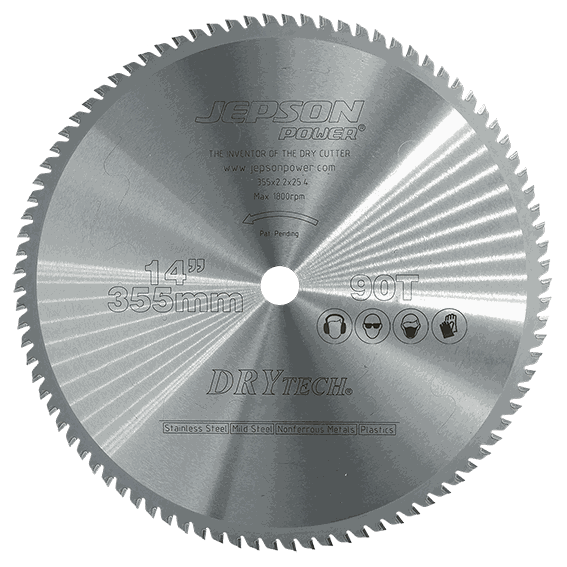

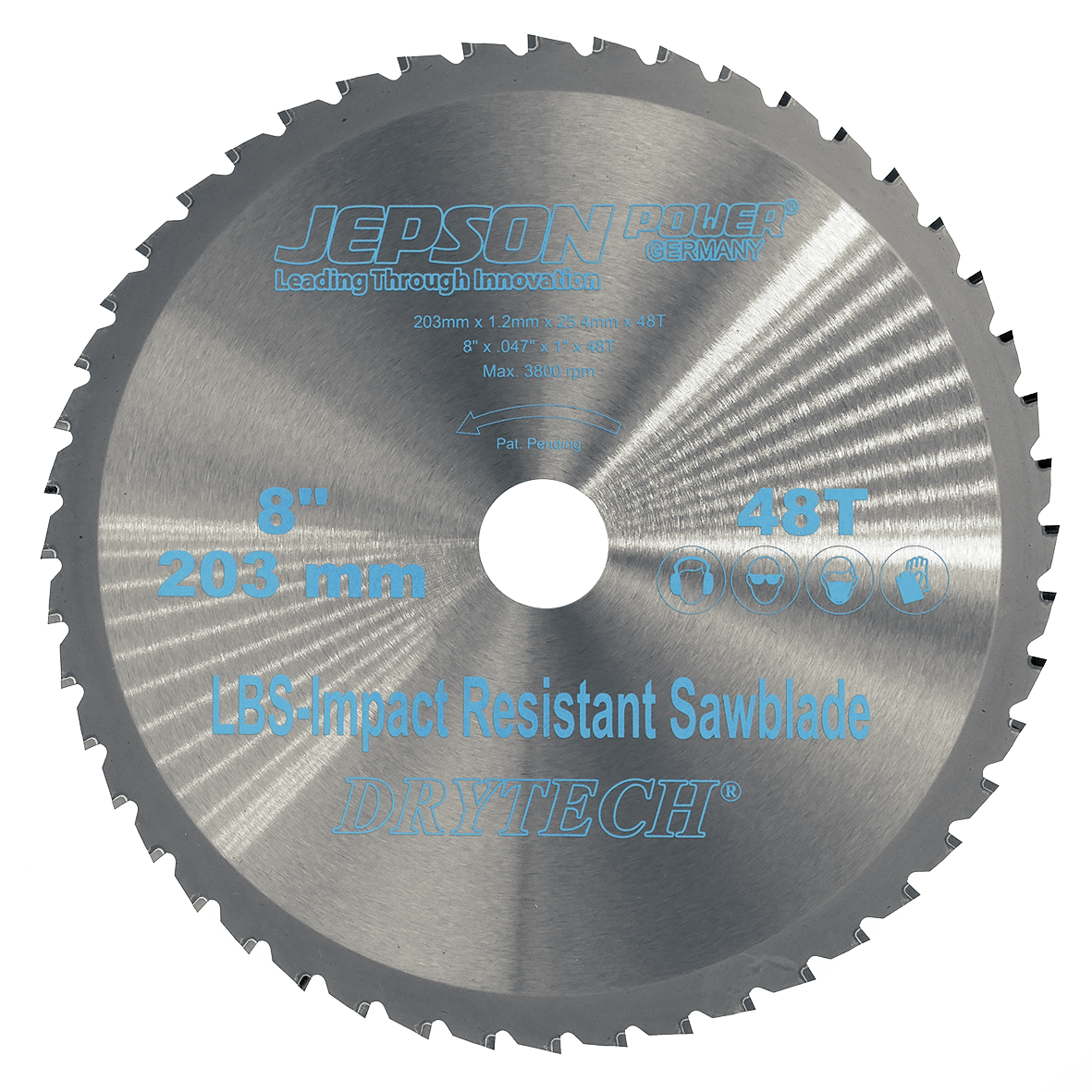

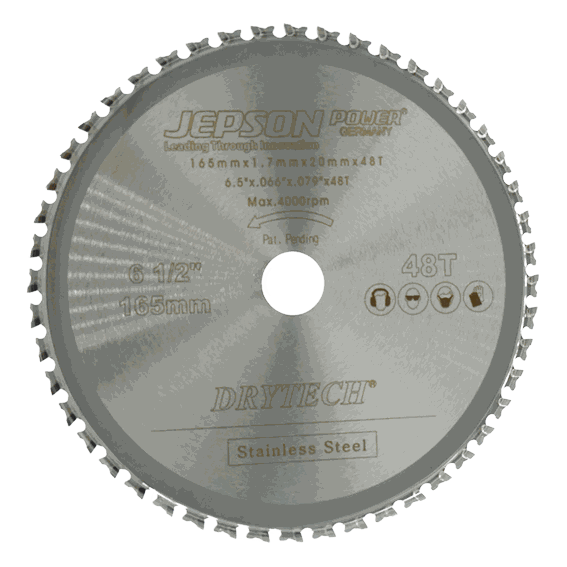

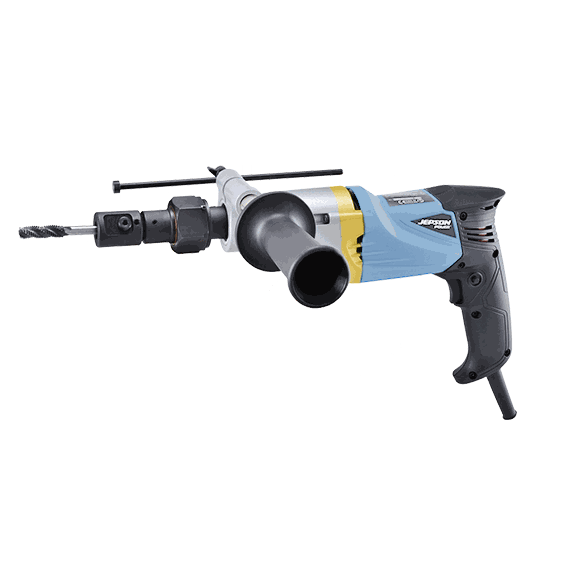

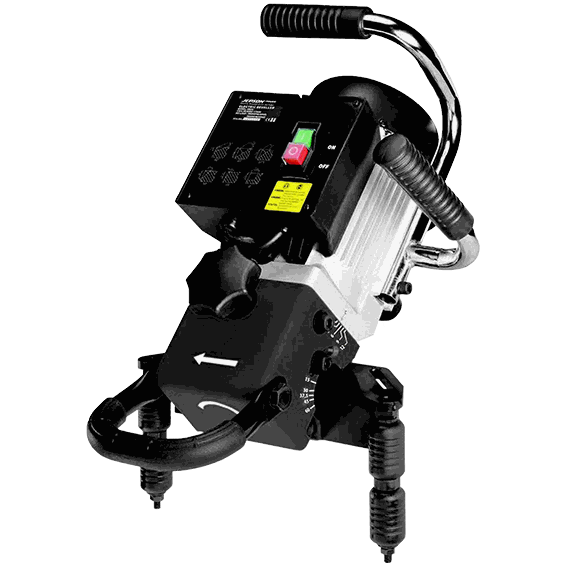

seit 1984 ist dies der Leitsatz von Jepson Power, dem Erfinder der Dry Cutter Technologie, in der laufenden Entwicklung von innovativen und hochwertigen Maschinen und Sägeblättern für die Verarbeitung von Metallen und Verbundstoffen. Mit unserer Technologie verläuft der Sägeprozess schnell, fast gratfrei, ohne Kühlung und mit einer hohen Standzeit. Dank langjähriger Erfahrung, fachkompetenten Produktberatern und einer Research & Development Abteilung, ist Jepson Power in der Lage, innovative und maßgeschneiderte Lösungen wie speziell beschichtete Sägeblätter zum Sägen verschiedenster Arten von Edelstahl schnell anzubieten."

Sowohl unsere Maschinen, als auch unser Team überzeugen durch höchste Leistung und Belastbarkeit.

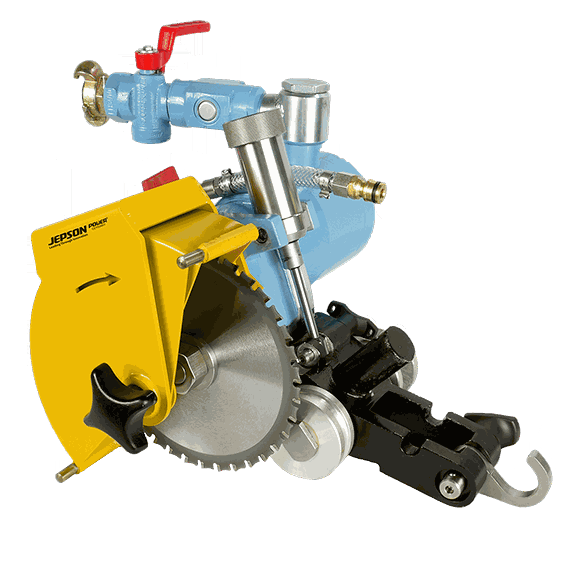

Wir sind ständig in Bewegung, denn bereits heute werden die nächsten Generationen unserer Dry Cutter Maschinen mit ihren einzigartigen Sägeblättern in unserer deutschen Produktionsstätte in Eschweiler entwickelt und getestet. Unser täglicher Ansporn: schneller Sägen, bessere Standzeiten und größere Schnittbereiche zu erzielen!

Tolle Auswahl an gut verarbeiteten, durchdachten Sägen für die Industrie und exzellenter Kundenservice.

Beste Dry-Cut Säge, die ich je benutzt habe!!! Ich mache seit über 25 Jahren verschiedene Fertigungsarbeiten und diese Säge übertrifft alles, was ich bisher benutzt habe! Entgraten nach dem Schnitt ist jetzt optional!

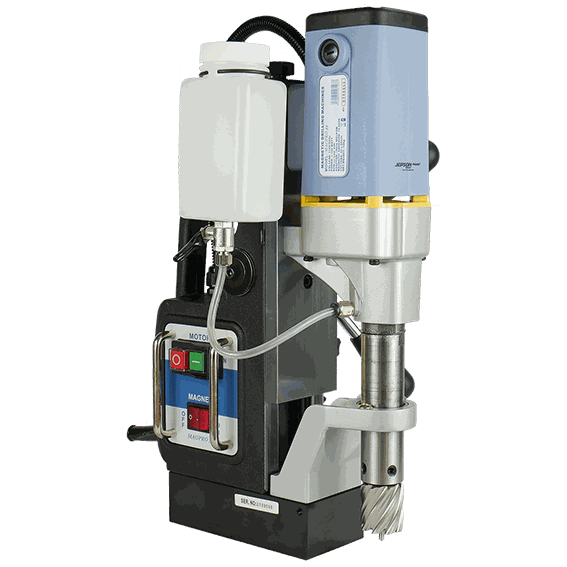

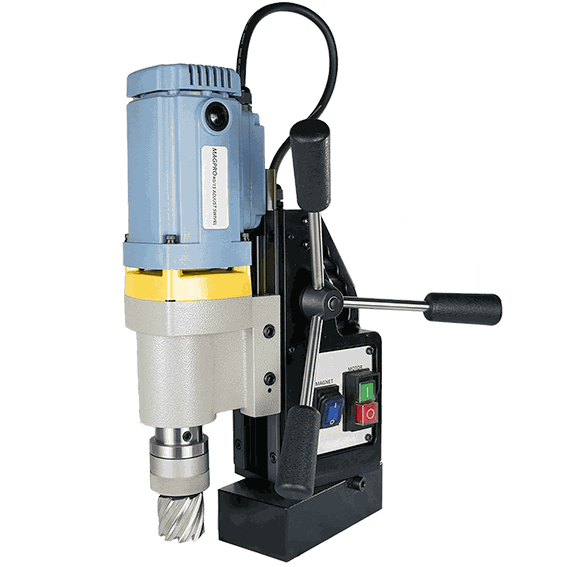

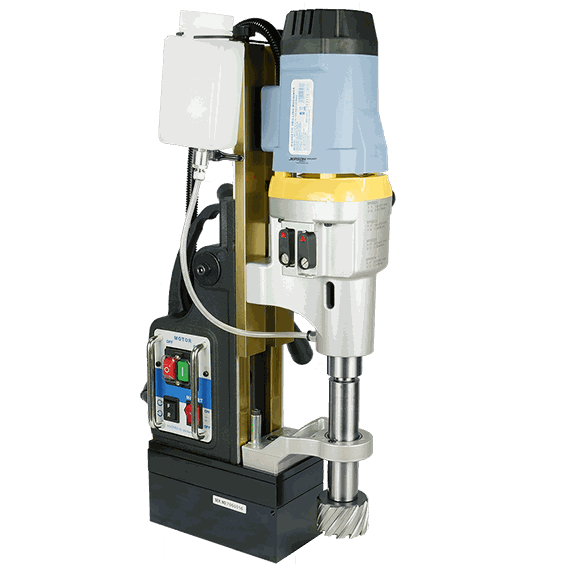

Ich habe einige Ersatzteile aus Rom, Italien, für unseren MAGPRO 35 bestellt und der Service war einfach exzellent. Teile kamen am nächsten Tag. Vielen Dank!

Die besten 2.000 €, die

ich je ausgegeben habe.

Der Stapel mit den 35°-Schnitten hätte sonst fast

einen ganzen Tag in Anspruch genommen und hat jetzt

nur 2,5 Stunden gedauert.

freuen!

freuen!